WARDCAM: Powerful, Simple, Fast

Easy To Use

Easy To Use, Clutter Free Interface, Context Sensitive Menus

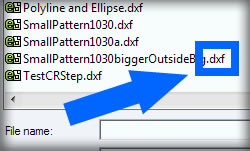

DXF

Accepts standard dxf files from any CAD/CAM software

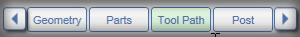

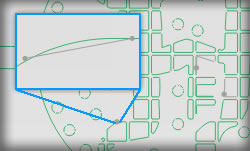

Intelligent Auto Tool Path

Set your toolpath automatically without your tool crossing over any previously cut contours.

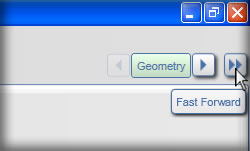

Fast Forward »

Fast forward through the whole process and go straight to posting your CNC file and Job Report

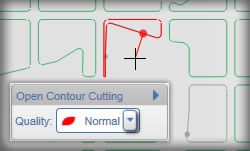

Choose different Cut Qualities and Leads for your contours

Squareness of a gantry system is critical to cutting accurate parts. The X-Classic Controller ensures squareness off of two independent home switches on the gantry axes. At the end of each homing cycle, the gantry axes are realigned to their calibrated state. From that time on, the system is continuously monitoring the travel of the motors. The operator is notified on-screen if the gantry motors ever become misaligned.

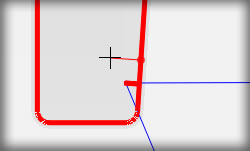

Partial Cut Qualities

Choose different cut qualities for specific sections of a contour

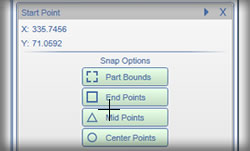

Custom Start Point

Set your start point wherever you like with snap options: Part Bounds, End Points, Mid Points, and Center Points

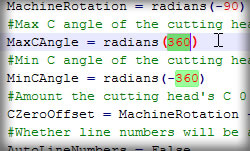

Customizable Post Processors

You have the ability to fully customize your post process

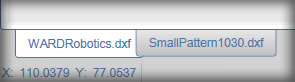

Tabbed Files

Open Multiple Files with Tabbed Navigation

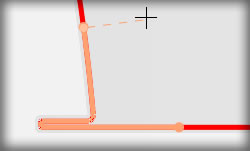

Open Contour Cutting

Cut any Open Contour with the Cut Quality of your choice

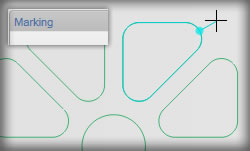

Marking

Marking, Etching, and Slit Cutting

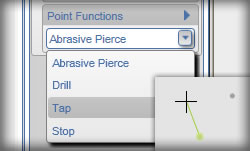

Point Functions

Mark points for functions like Abrasive Pierce, Drill, Tap, Stop and User Defined functions.

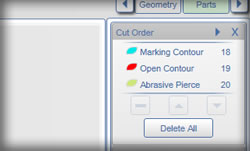

Cut Order

Easily adjust contour cut order. Delete single contours, move cuts up or down in the line, or delete all and start from scratch

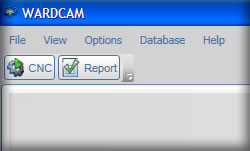

CNC & Job Reports

Create CNC File with standard G+M code and create Job Reports

Intelligent Error Checking

Any stray contour, open contours or points will remain the color gray. This is useful if you weren't able to see it before and need to delete it. In addition, it makes it easier for you to see open contours for marking slit cuts and etching.

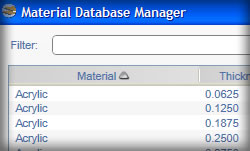

Automatic Feed Rate Calculation

Feed Rate Calculator in Material Database will adjust settings automatically based on machineability. You can also manually adjust all settings.

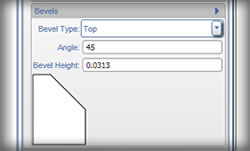

Bevels

Custom bevel settings with a preview image so you can easily see what the bevel will look like.

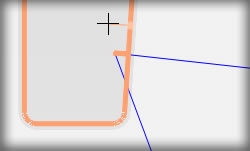

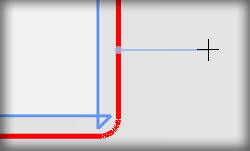

Visual Tool Offset

The visual representation of your tool offset makes it easy for you to see exactly where you will cut which Allows you to see if your contour is too small for your tool to fit.

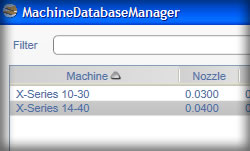

Material Database & Machine Database

With the Material & Machine Databases, you have practically unlimited control over what materials and cutting systems your programming recognizes.

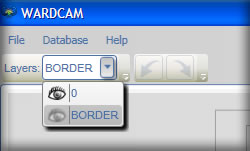

Layers

Hide and reveal layers of your part. Easily hide guide marks or measurements from your original file. Hidden contours will not be cut.